Wet pressing process is a new type of modern technology, which is widely used in insert &inner tray packaging options. Molded pulp products made from 100% biodegradable & compostable material, sugarcane fiber (as known as bagasse), bamboo fiber, wood pulp, recycled paper pulp and other natural plant fiber.

The products not only with very smooth surface and finish that enhance your brand values, but superior packaging performance, protection, cushioning, nesting and stacking capabilities, saving space, assemble and transports cost.

Plastic-Free packaging trays manufacturer

Model:BNT-HA071 Color:in white Size:custom made base on products Material:sugarcane pulp fiber/bagasse Packing:stacked,polybag,standard export carton Sample tooling & sample lead time:10days Production tooling lead time:15days MOQ:10000piece

Custom made molded inserts for hardware tap packaging

Model no.:BT-IP001 Material:Sugarcane pulp/bagasse Stype:folded Usage:protective packaging material Feature:recyclable sustainable MOQ:10000pcs in white Color:In white,black,custom base on Pantone color possible

Molded pulp for e-cigarette interior protective packaging

Feature:eco-friendly,environmentally. Material:bagasse pulp fiber Process:Molded pulp Color:in white (bleached) Qty: 10000pcs in white MOQ Sample mould &sample lead time:10days Production mold lead time:12days Production lead time:20days

Wet Press Pulp Packaging Manufacturers

Feature:Natural molded pulp tray with blister packaging Color:brown/natural Size:customized Qty: 10000 pieces Material:Recyclable sugarcane fiber+bamboo Sample lead time:10days Production tooling lead time:12days Mass production lead time:20days

Customized Paper Pulp Box Wet Press for Watch Packaging

Shape:Square Color:In white Feature:molded pulp lid +molded pulp base,elastic ribbin closure Type:Wet press Material:Sugarcane fiber or name bagasse

Sustainable Moulded Paper Pulp Packaging for iPad

Feature:sustainability eco-friendly Color:in white Material:bagasse/sugarcane plant fiber Type:wet pressing Size:customized MOQ:10000 piece

Renewable Moulded Fiber Products for Tea Package

Type:Wet press MOQ:10000piece Material:sugarcane plant fiber Size:Customized Packing:stacked, polybag,carton Sample mold & sample lead time:10days Production mold lead time:12days

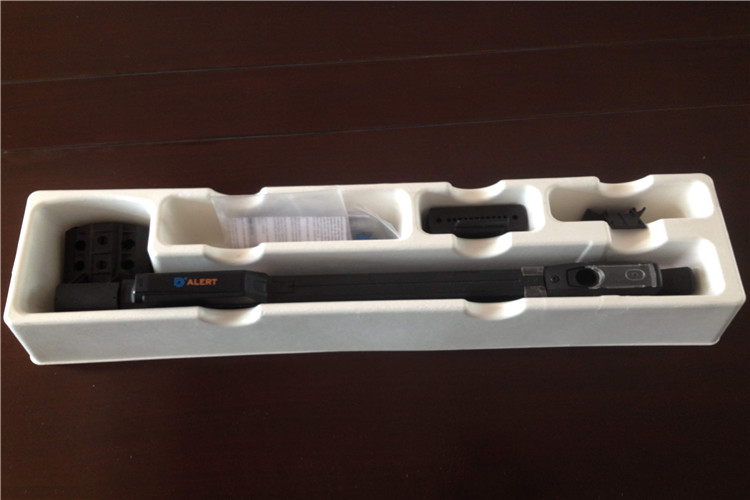

Moulded Pulp Based Packaging for E-cigarette Insert

Item No.:BNT-EC020 Material:Paper pulp Type:wet press Color: in white MOQ:10000pcs Sample lead time:10days Production mold lead time:12days

Wood pulp packaging for Digital Camera Insert

Type:Thin wall pulp tray Process:Wet press Color:in white Design:4 side-folded style Material:bagasse & wood pulp Quantity:10000piece

Molded pulp manufacturers for thermometer insert packaging

Item Number:BT-EP030 Material:sugarcane plant fiber Color:in white Packing:stacked,polybag,carton,pallet possible Sample mold &sample lead time:10days Production tooling lead time:15days

Page 4 of 10« First«...23456...10...»Last »