How we develop your products

Bonito Packaging's in-house design team with the capacity of developing a custom packaging, we could help you run from concept and ideal to production. Bonito can provide you innovative engineering and design solutions as fast as anyone else in the industry.

"All in one" packaging concept, We try best to make full packaging with one material, to make biodegradable, recyclable and sustainable packaging, Utilizing modern molded pulp process and equipments, Bonito know how to meet your requirements, we excel at clients satisfaction, industrial molded pulp inner protective and cushioning packaging.

We offer a simple and efficient 4 steps development process:

Assessment and Analysis

Design Concepts

Prototype and Test

Tooling and Manufacture

Manufacturing Process

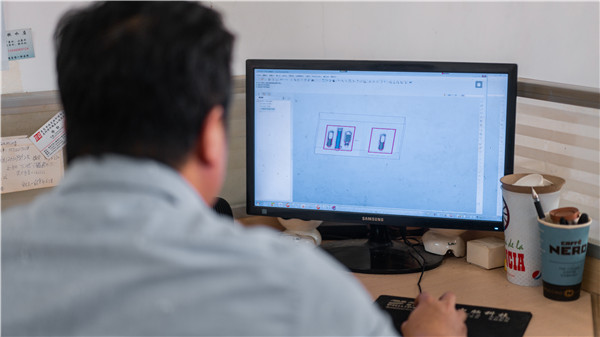

SolidWorks 3D software, drawing by STEP or IGS format is available. You should providing us 3D drawing review, our engineers will check and learn if modify or not, then provide you solutions, response within 24 hours, highly active! If you don’t have 3D drawing it is possible expressing your product to us to design, within 48hours response with drawing design.

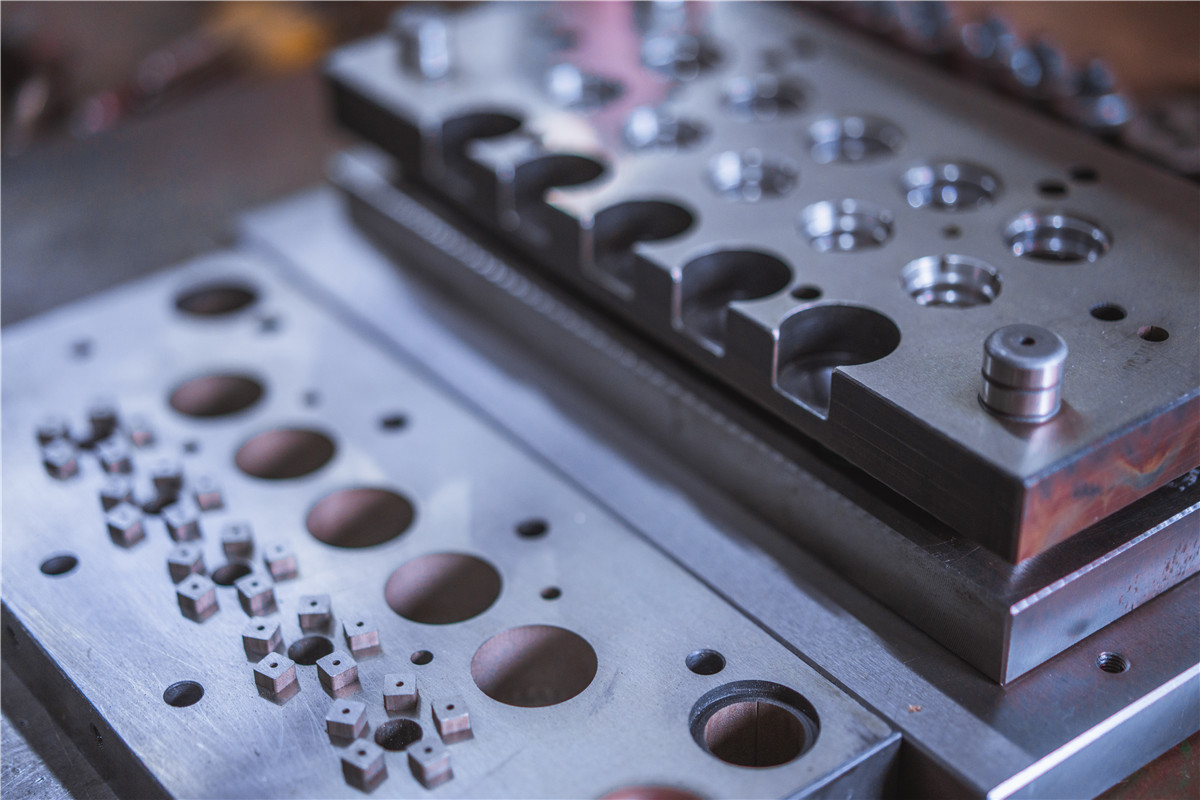

Using CNC technology, The tooling material is #737&636,whole new aluminum (copper and steel available) not recycled material, make sure products with good quality. What is more, in-house tooling center is staffed by years of skilled engineer who is highly respected in molded pulp packaging industry, be sure tooling ready in agreed date, no delay!

Made from 100% biodegradable & compostable eco-friendly material, selected grades of sugarcane fiber, also named bagasse, bamboo, wood pulp, wheat straw, paper pulp or other virgin pulp when combined with water, a pulp slurry of proper consistency is created. Difference alternative material options for your choice, meet consumer custom requirements. Waterproof and oil resistance function workable, adding food-grade waterproof & oil-proof additive into the pulp.

The pulp and water through pipe running arrive forming machine where process associated with molding in desired shape, by suction and vacuums make the water run steel nest out , pulp remain then your products be formed with desired. The pulp is wet and soft, the worker can pick out the dirty parts if he or she found.

The fibrous formed part be transferred to heat pressing machine whereby it is carefully dried, with 20~30 tons pressure force(20t,25t, 28t, 30t options), through 2~3 minutes(based on specific product, the higher &larger dimension the more heating time needed) thermoforming, via a vacuum process, the sugarcane fiber accumulates to a desired thickness and strength while excess water is removed, no moisture and bactericidal, then semi-finish products be ready, unlike dry process molded pulp under the son or heater systems, after trimming products finished.

Before trimming, our quality controller would random checking the products’ weight, density, strength & hardness or other parameters that clients requires. for tableware or medical pulp tray water & oil resistance. Once problem be found at this stage, we will adjust and fix right away, in case of the products be made out waste, save cost.

Semi-finish products be transfer to die cutting machine, it can be cutting on specific dimension,+-0.5mm tolerance high precision, flat & simple item can trimming, if the products not on flat design but with slope design or complicated structure then punching mold requires, punching tooling more precision +-0.2mm tolerance, great edge die cutting looking.

After products die cutting finished, finish products be transfer to quality checking line, inspection one by one,100% inspection, the main quality like dirty, black dot, broken, wrinkle issue, rough selvedge etc. all be inspection by trained and responsible workers.

At this stage, our final quality controller will checking by random, if the reject proportion pass must re-checking to whom be responsible for the parts until no any issue, we make sure with great quality before warehousing.

Normally, packing method would be like this way :stacked one by one, in poly bag, then into export cartons. Inner box, corner protective, on the pallet, safety and cushioning based on consumer available.

Once products passed checking and packing good, then all the goods be storage in the clean ,dry, safety warehouse, with detail, clear remarks and record, easy to find out when you need delivery.

If no specific requirements from clients, we should stacked each carton into the container, as many as cartons try to, save shipping cost, but not damaged at the same time. Some clients need specific like on the pallet, height not pass 1.6m,no problem, we have experience on it.

Design

BonitoPak help you from design concepts to production runs for both small and large projects. we own latest molded pulp equipment and technology capacity in industrial packaging. with in-house design team and tooling room, be sure tooling rapid finished, testing and work for production.

Analysis & Engineering

Our design engineers have rich experience in molded pulp process, more than 15years in this industry, not only in wet pressing design and tooling but dry pressing. With thousands of design projects make them know how-to-do and workable for production.

Prototyping

With a design file, a rapid prototype can be created, we can make simple 3D printing sample to review, sample parts are generated for evaluation, discussion and testing. Clients don’t need to pay cost at this stage, we cover the small cost. If changes are required, then we can learn where the problem from, fix and modify it, not waste time and cost. The prototype is quite useful that present a visible ideal to customers.

Sample Tooling

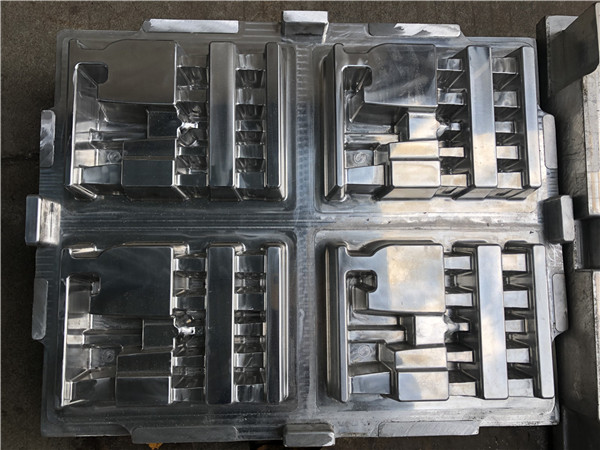

For new items we always suggest sample mold first, sample mold with one cavities to make samples, like 10pieces,the sample mold can’t use for mass production, because of production tooling need high capacity of output, if sample need small revise and modify ,cost is small, but if production mold be made out then you need revise production mold the cost is high. The testing sample should the same quality as production one. What else, the sample mold not refundable, we get sample mold cost only, as we have pay sampling cost on it. Difference from blister that sample cost returnable.

Production Tooling

Production tooling is constructed in-house utilizing CNC technology to ensure accuracy and quality, One full set production mold include one set forming mold,2 sets thermoforming mold and 1set die cutting mold ,some items punching mold requires ,it depends on specific case. The tooling material often use new airline aluminum, but copper, steel available which can production for longer time.

Mold & Tooling

Our products belong to thin-wall type molded pulp, and process divide into wet pressing & dry pressing.

Wet pressing mold

The forming part with 2 difference process

one is “grout-in” the pulp and water run into the barrel then water be absorb by vacuums progress. It advantage is higher production output, because of staffs transfer to thermoforming need shorter time, disadvantage is need bigger draft angle, thin thickness, normally 0.8mm thickness, range 0.6~1.0mm thickness available.

Another forming we call it ”salvage” the pulp and water that is in the pulp pipe the forming mold is rising up, then desired shape finish. It advantage is smaller draft angle like 3degree,4 degree workable, good looking and high performance. what is more, thickness can reach 1.2mm which grout-in process hard to reach. disadvantage is slower capacity, after forming then transfer by special “car “ to the thermoforming step, but we have enough equipment to meet your production requirement, no problem. If you need high quality and cost supportable we suggest this one.

The forming mold can be aluminum material, also ABS possible, but hot pressing must aluminum, copper or steel, cannot ABS, because of high temperature about 200degree,ABS cannot meet that. The thermoforming step is the same, just forming little difference.

Dry pressing mold

The mold cost much cheaper than wet pressing mold, because of dry pressing no thermoforming mold and the mold material is recycled aluminum. After forming then transfer under the sun, if bad weather must in heat dry system to let the pulp drying, once pulp get dry using shape molding to press, the result is product with rough appearance, its advantage is products with thickness of 2.5mm or 3mm performance, drop testing may passed, so dry pressing molded pulp tray be often used in home appliance, corner protective, suitable for large and heavy products. Its advantage is stacked with big space, high warehousing and deliver cost, rough surface not high quality. One full set dry pressing mold including 1 set forming,1set shape press mold, some items with trimming mold.